If you are interested in learning more about garage floor coatings, specifically why they are such a great investment and add both durability and beauty to your garage, you might have wondered… what’s the deal with the flakes? In this guide, we’ll take a closer look at those tiny little flakes to better understand what they are, how they’re used and why they’re so important. Let’s get started!

The flakes in question are often referred to as vinyl flakes, color flakes, color chips or epoxy paint chips, and are actually polymer paint aggregates made up of a combination of acrylic and vinyl resins. This material combination creates an ultra-thin flake that is only 4-5 millimeters in thickness. The flakes are random in shape, and for garage floor applications, you’ll typically want to use flakes that are ¼” in diameter. They are available in over 150 custom colors and can even be color matched. The flakes closely resemble super thin pieces of vinyl, and they do not color bleed when they become wet. Lastly, the flakes are fade resistant, and will never become discolored, even in direct sunlight.

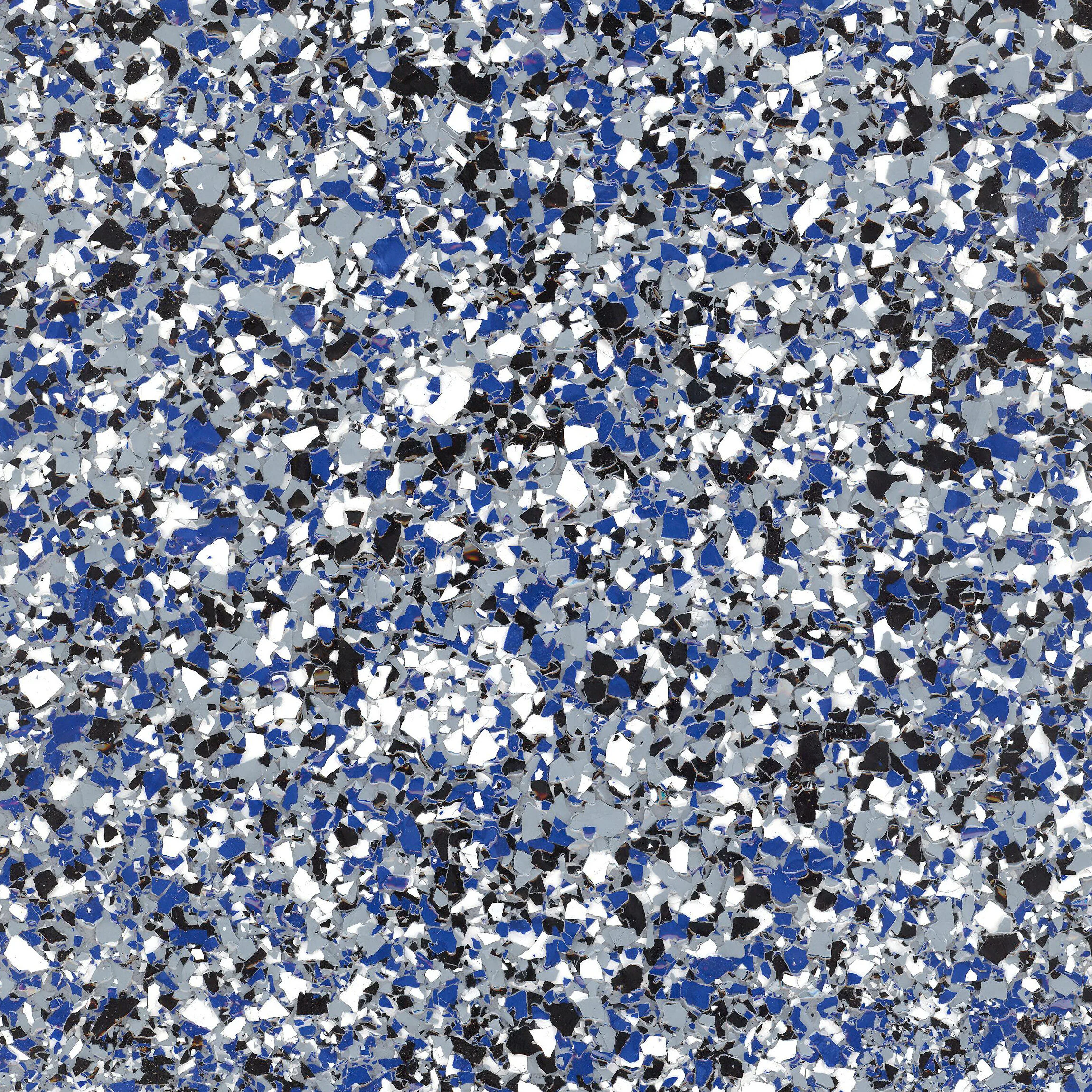

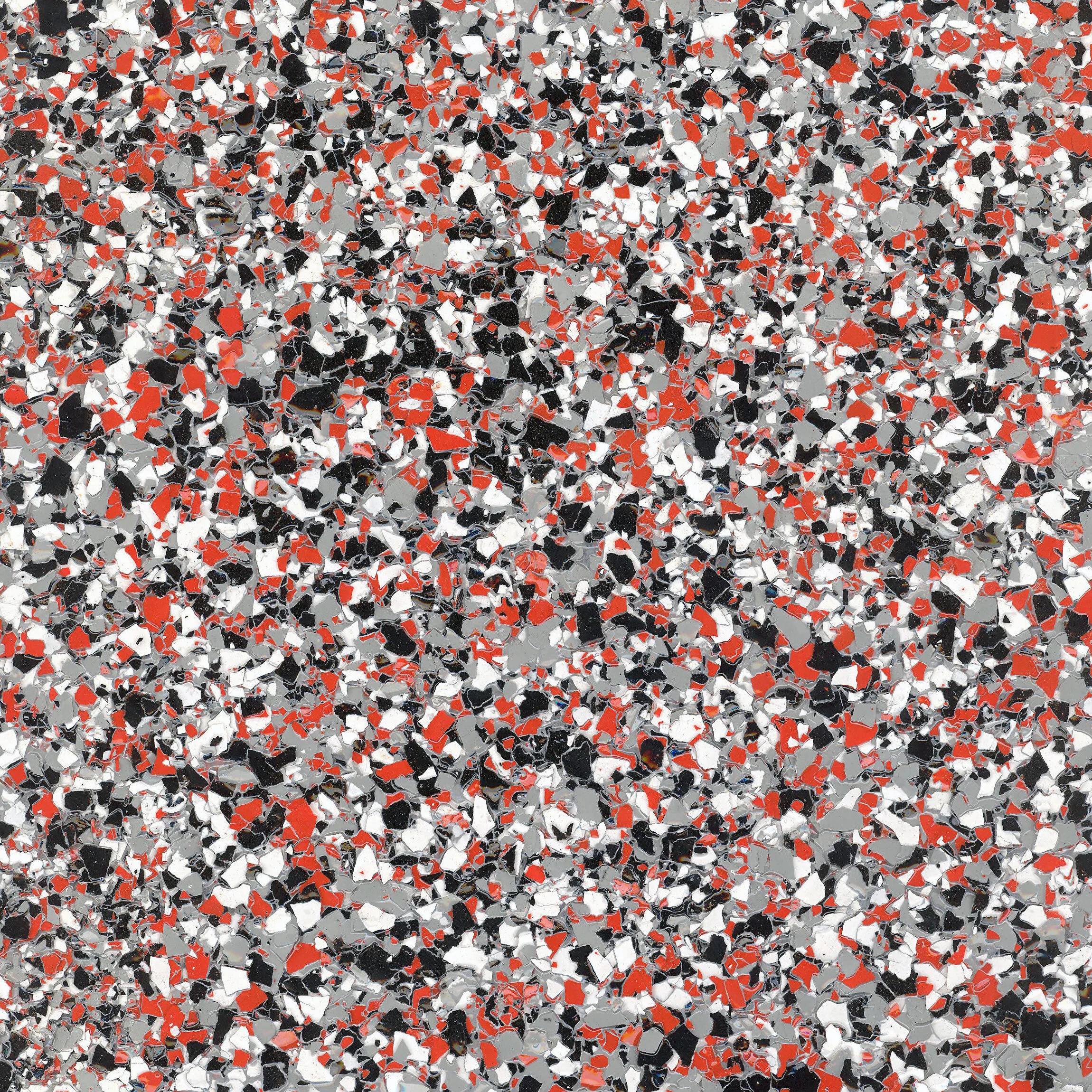

The fun part about these little flakes is the colors they come in. Not only do they come in a wide variety of individual colors, but they also come in an array of three to four color blends that can perfectly coordinate to your home’s color palette, as well as to the base coat that you have selected for your new garage floor coating. Base coats come in a variety of colors as well, with the most common being grays and tans. Both the individual flakes and the color blends can also be customized to your exact specifications. When creating your own color blend, it’s recommended that you pick a darker color, a lighter color, and a mid-range color and then experiment with blend ratios. Also, remember that the flakes will be on a surface several feet below you, so it’s best to try the blend ratios out on the floor vs in your hands.

To apply the flakes, your garage floor coating installer will broadcast them on top of your base coat to full rejection – meaning that your entire floor will be completely covered, and then some, to ensure that no bare spots remain. The flakes are broadcast onto your base coat immediately after it is applied, to ensure that the flakes are able to bond properly. The flakes are broadcast from a bucket, and are thrown into the air, almost like they are being used to feed chickens, and are not thrown directly at the floor. This allows for the flakes to disperse much better as they arc up into the air and then land back down on the coating in a nice and even dispersal. Tossing the flakes directly at the floor will result in unwanted “V” shaped patterns that are difficult to correct.

After the floor is dry, which takes between one-two hours depending on the weather, floor scrapers will be used to lightly scrape the floor to remove extra and raised flakes. Because the floor was covered with flakes to rejection, the base coat will not be damaged by the scrapers. Using a leaf blower, the excess flakes are blown into one corner of the garage for recovery, the floor is thoroughly vacuumed, and then a clear polyaspartic top coat is applied to give the floor its beautiful shine and durable protection.

So back to the flakes… other than to add visual appeal to your floor, why are they used? The primary reason flakes are used in garage floors is to add the crucial element of slip resistance. With only a base and top coat, and no flakes, your floor would be incredibly smooth and slippery. Add to that the fact that our garages are prone to wet messes and spills, and you’ll have a safety hazard on your hands. The flakes add just enough traction to the floor to ensure that you can safely walk on it without any concerns, even when water and other liquids are present.

The next reason flakes are used in garage floor coating applications is that they are flexible and strong, and add an additional layer of thickness to your floor. This helps improve both the durability and impact resistance of the surface.

The expert garage floor coating installers at Twin Cities Resurfacing would love to meet with you to discuss how a garage floor coating system (including flakes!), can drastically improve the look and durability of your garage. Click the link below to get started!